The Importance of Sandwich Dies in the Packaging Industry

In the dynamic world of packaging, where aesthetics, efficiency, and sustainability take center stage, there exists a pivotal instrument that shines as a transformative force: the Sandwich Die. These meticulously crafted cutting tools have not only reshaped but revolutionized the packaging industry, offering a plethora of advantages and characteristics that are redefining the landscape for both manufacturers and brand owners.

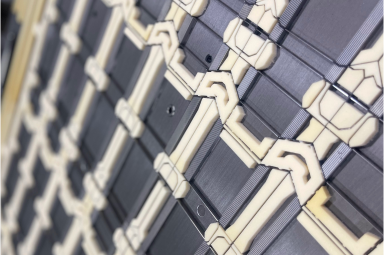

Precision Cutting : Enhancing Packaging Quality

The core appeal of the Sandwich Die resides in its unparalleled precision. These dies provide precise and consistent cutting, ensuring uniform packaging shapes and dimensions that lend a professional appearance to products.

Customization : Crafting Unique Brand Identities

In an era where brand differentiation is key, Sandwich Dies empowers companies to create custom packaging designs that cater to unique branding and product requirements. This level of personalization sets brands apart from the competition.

Speed and Efficiency : Accelerating Production

Time is money, and Sandwich Dies saves both. By automating the cutting process, they significantly increase production speed while concurrently reducing labor costs. The result is faster time-to-market and a competitive edge in the industry.

Waste Reduction : Greening the Production Line

Precise die-cutting is not only about perfection; it's also about sustainability. By minimizing material waste, Sandwich Dies makes production more eco-friendly and cost-effective, aligning with today's environmentally conscious consumer preferences. It also reduces the per carton cost of the die-cutting process.

Versatility : Materials beyond Boundaries

The versatility of Sandwich Dies is truly impressive. They can be employed with a variety of materials, including cardboard, paperboard, corrugated board, electronic components, and even plastics, broadening their application across industries.

Repeatable Results : Ensuring Consistency

Consistency is the hallmark of professionalism, and Sandwich Dies ensures that each cut is identical and each crease is consistent. This consistency maintains the quality and integrity of your product.

Enhanced Product Presentation : Designing for Impact

Product presentation is everything. These dies allow for intricate designs and window packaging, enhancing product visibility and appeal. This feature holds particular significance in the competitive world of retail.

Prototyping Capabilities : Perfecting Your Vision

Innovation demands iteration. Sandwich Dies are invaluable for creating sample packaging during the design and prototyping phase, enabling testing and refinement before mass production.

Ease of Maintenance : Built to Last

Durable and requiring minimal maintenance, Sandwich Dies contribute to long- term cost savings. They are built to withstand the rigors of high-volume production, ensuring longevity, reliability, and with the re-knifing capability of upto 15 times.

Broad Industry Application : Versatile Solutions

The versatility of Sandwich Dies extends across industries. They find applications in food, cosmetics, electronics, and retail, providing tailor-made packaging solutions for diverse products.

Cost-Effectiveness : Efficiency Meets Savings

By increasing efficiency and minimizing material wastage, Sandwich Dies translates to reduced production costs & with the possibility of re-knifing, ultimately improving a company's bottom line.

High Durability : Investing in Longevity

Manufacturers need tools they can rely on. Sandwich Dies are designed to withstand the demands of high-volume production, ensuring they remain a trusted part of your manufacturing process for years to come.

In conclusion, Sandwich Dies has emerged as a transformative force in the packaging industry. Their precision, customization capabilities, and efficiency benefits are helping businesses meet consumer expectations and market demands. As we navigate an era of evolving consumer preferences and sustainability concerns, these dies are proving to be indispensable tools that empower companies to excel in the art of packaging.